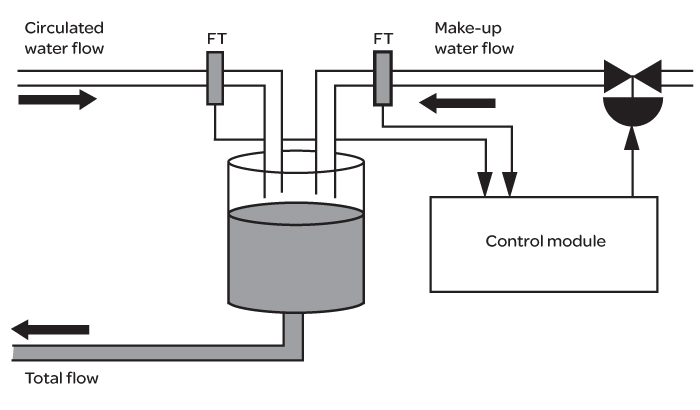

Make-up Water Closed Loop System

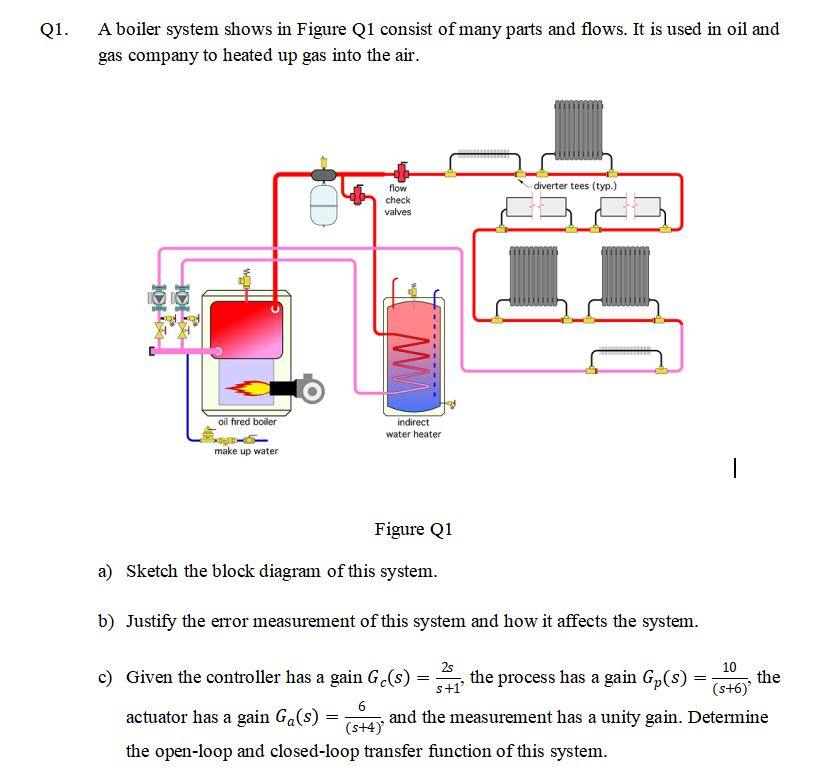

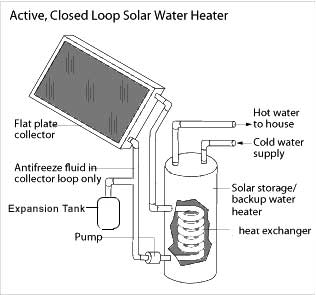

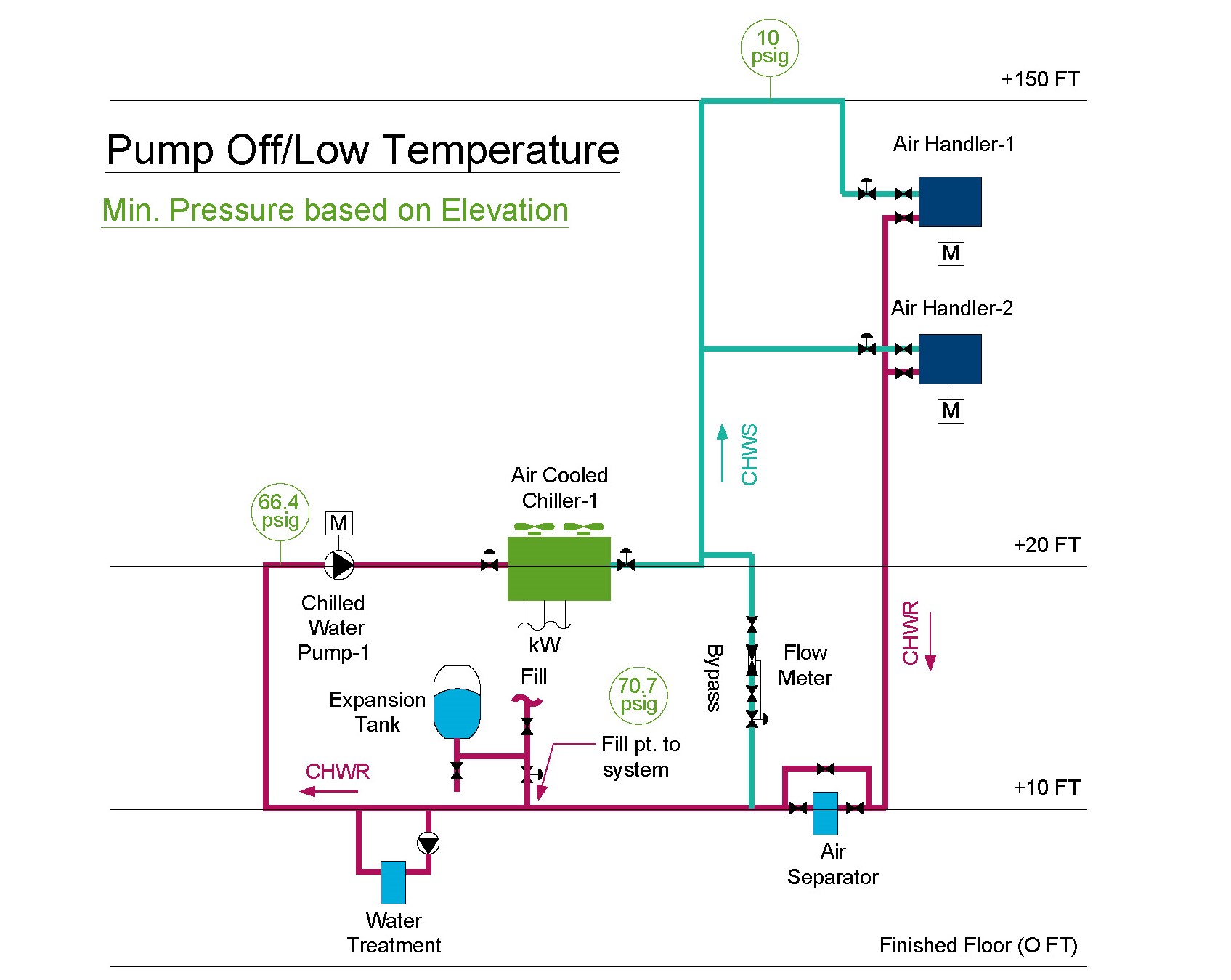

Make-up water closed loop system. To preserve the longevity of the closed-loop system it is necessary that the makeup water for the system first be treated to reduce the suspended solids and certain dissolved ions. Industrial glycol is composed of either ethylene or propylene glycol a corrosion inhibitor and water. Make-Up Water Assembly Initial Fill Air Purge.

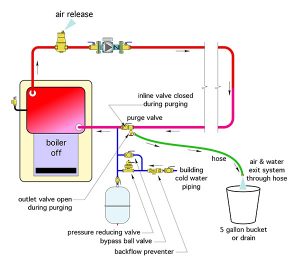

Nearly all closed loop hydronic heating and cooling systems are supposed to be filled with water or a mixture of water and antifreeze. They have a number of advantages over open water systems including greater efficiency and lower maintenance requirements but it would be wrong to think of them as maintenance-free. The close the valve and open a radiator valve on the top floor until the pressure drops back to 15 or so.

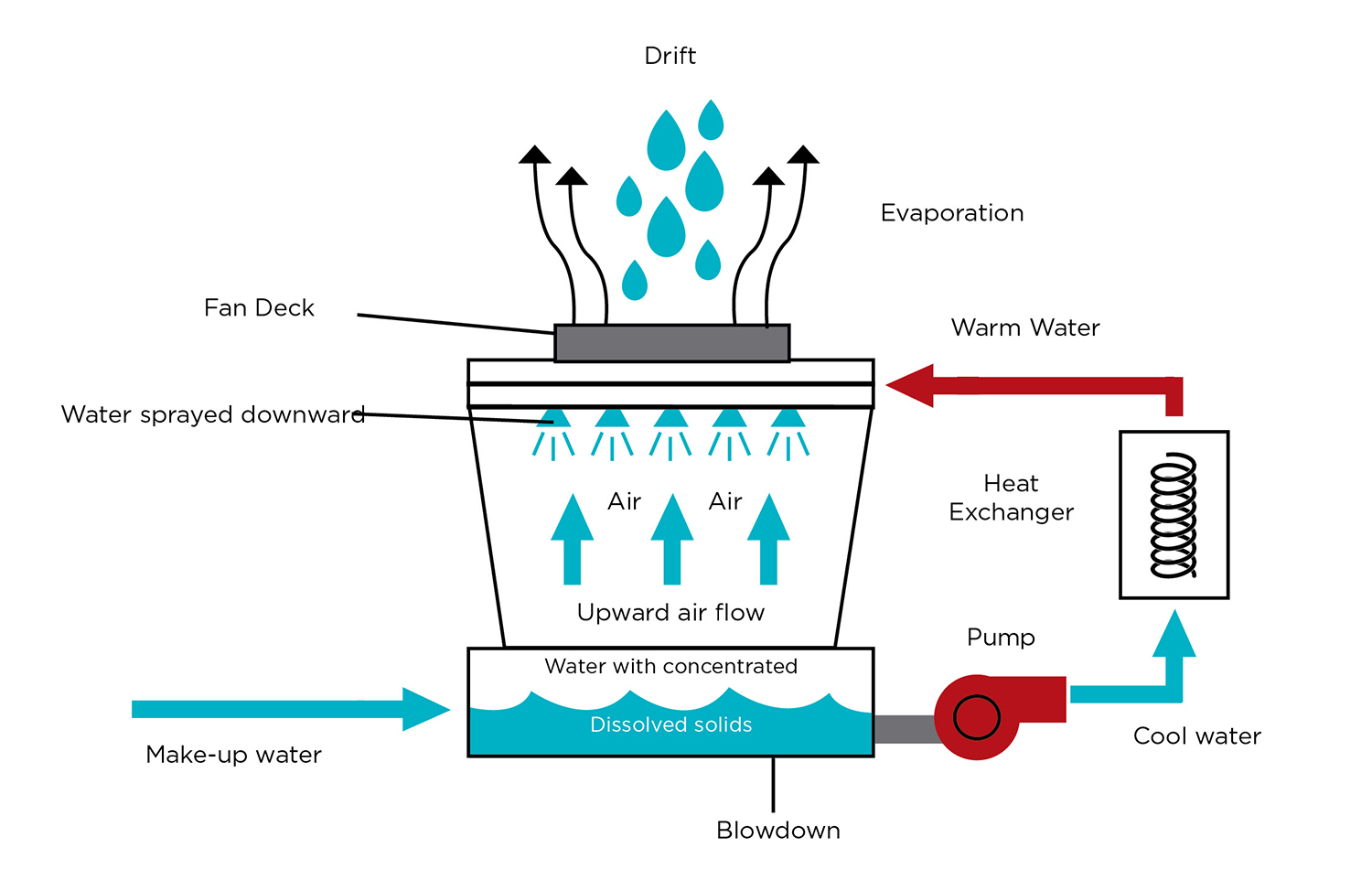

The only make-up water normally needed is replace water loss from leakage at pump seals expansion tank overflow or surface evaporation from system vents. A cooling system that uses evaporation as the means of rejecting heat consumes water and requires make-up water to continue to operate. Most commonly the piping in.

Head of water to top of system meters The quantity of make-up water for a closed system should average less than 01 of the system volume per day. There is little or no makeup water. Typically these systems are pressurized.

The presence of dissolved gases such as oxygen or carbon dioxide microbiological growth or deposits of particulate matter is of concern and should be treated. Make up water open tanks and system vents can transport oxygen into the closed loop. How do they get into the system.

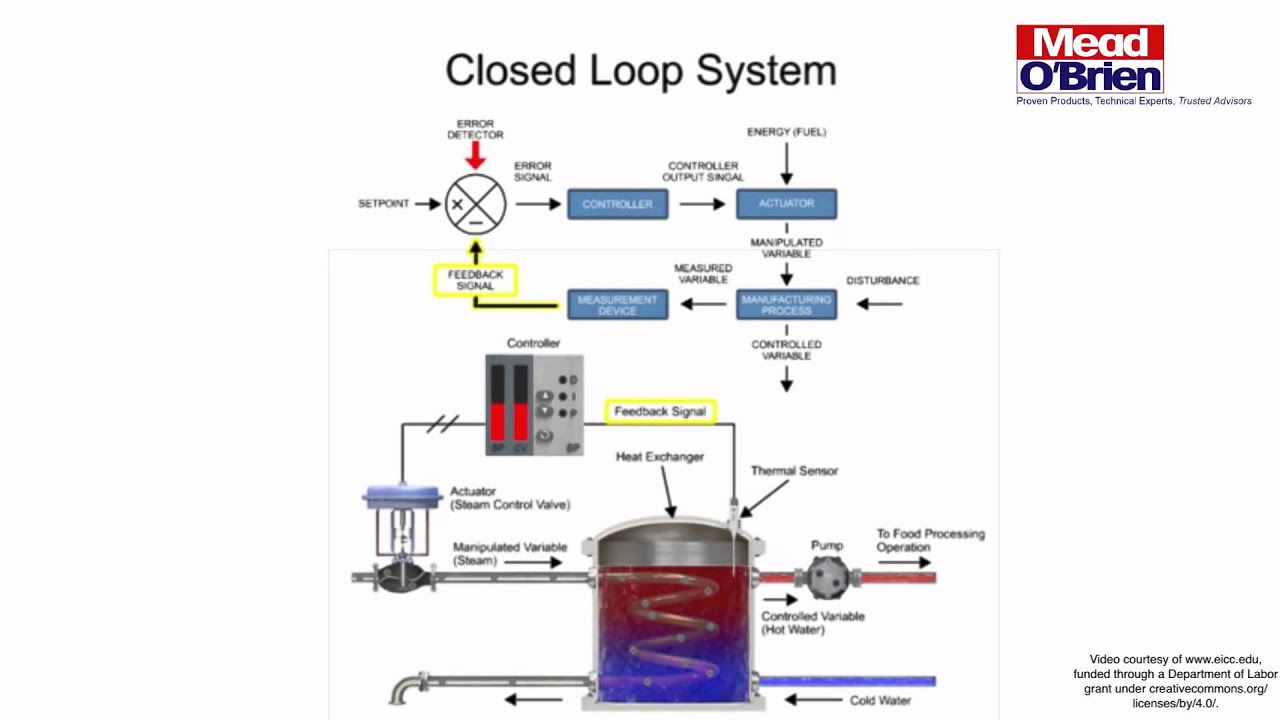

This posts helpful to understand the basic principle of a Control loop and its components. This equates to a sodium sulphite consumption of approximately 10 ml per month per 1000. Generally demineralized water is used for closed-loop cooling water makeup but chemical treatments are required to prevent corrosion and in some systems freezing.

When the system was initially filled more than likely it was with city water. Untreated systems can suffer serious corrosion damage from oxygen pitting galvanic action and crevice attack.

The only intentional air in the system is.

Reducing the contaminants and debris in the system extends the entire systems life by lengthening the amount of. Untreated systems can suffer serious corrosion damage from oxygen pitting galvanic action and crevice attack. Many times these systems are neglected since leaks take. Make up water open tanks and system vents can transport oxygen into the closed loop. Industrial Glycol Application In Closed-Loop Water Systems. In a true closed loop the chemical treatment is added initially and is expected to remain in the loop for a long period of time - until the loop is drained either fully or partially - for repair. Make-Up Water Assembly Initial Fill Air Purge. The only make-up water normally needed is replace water loss from leakage at pump seals expansion tank overflow or surface evaporation from system vents. The answer is that closed loop systems are susceptible to corrosion and low pH.

The close the valve and open a radiator valve on the top floor until the pressure drops back to 15 or so. Make-Up Water Assembly Initial Fill Air Purge. Ad With 25 Off Everything Get Ready To Fill Your Basket To The Brim Entirely Guilt-Free. Most commonly the piping in. Industrial Glycol Application In Closed-Loop Water Systems. The only make-up water normally needed is replace water loss from leakage at pump seals expansion tank overflow or surface evaporation from system vents. Use Code CBBF25 At Checkout.

Posting Komentar untuk "Make-up Water Closed Loop System"